Hi all,

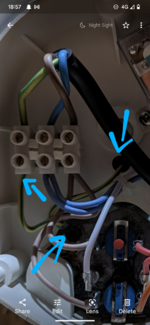

Just found that my water heater is dripping from within the electric box on the internal side of the heater. I assume this must be coming from where the heater rod/immersion enters the cylinder maybe. I can't see any other connections that side, everything else is the other side and its bone dry that end.

Any pointers on whether this can be fixed? Would it be a seal maybe? All sounds easy enough but with it being 24 years old i guess spares are probably an issue.

Cheers all

Gary

Just found that my water heater is dripping from within the electric box on the internal side of the heater. I assume this must be coming from where the heater rod/immersion enters the cylinder maybe. I can't see any other connections that side, everything else is the other side and its bone dry that end.

Any pointers on whether this can be fixed? Would it be a seal maybe? All sounds easy enough but with it being 24 years old i guess spares are probably an issue.

Cheers all

Gary