I have been having trouble joining wires in my Motorhome. I decided that all joints should be soldered and held with the shrink plastic. I could not find a 12volt soldering iron so I bought a 40watt cheapo.

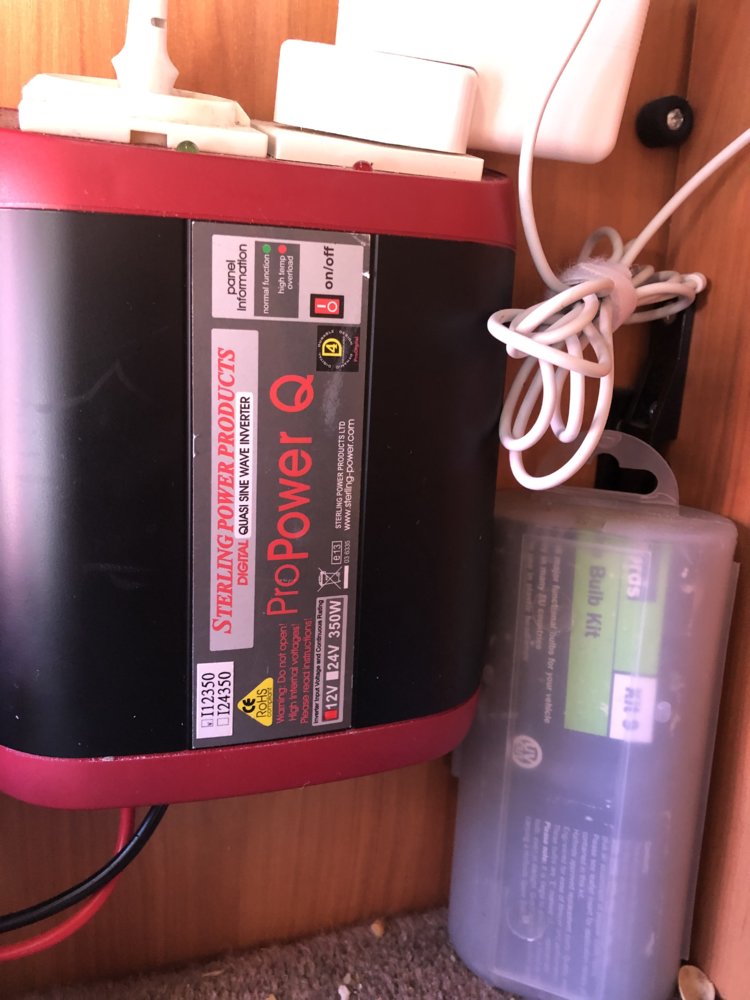

My inverter is a 350watt, adequate for charging toothbrush, computer etc.

Can I plug my soldering iron into this inverter?

Can I plug

My inverter is a 350watt, adequate for charging toothbrush, computer etc.

Can I plug my soldering iron into this inverter?

Can I plug