- Dec 31, 2010

- 2,635

- 5,822

- Funster No

- 14,797

- MH

- Frankia Platin i7900

- Exp

- Since 2010

Thought some of you would like this turning a hex on a component.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Subscribers do not see these advertisements

I saw it but I don't believe it. I'd love to see that in very slow motion.

I saw it but I don't believe it. I'd love to see that in very slow motion.

Subscribers do not see these advertisements

Apologies, but include me out! I hack metal, not electrons!I'm looking at upgrading my Tom Senior mill for a nice Bridgeport I've got my eye on. I was hoping to run it off a vfd, but I noticed the 3 feed motors are rated at 90volts dc, so that scuppers that idea for the moment and my wallet got a severe fright at the price of rotary phase converters.

There's a slim chance that the input transformer looks to have a 240v tapping (but 'tricity is the devil's work to me!) and I need to get my tame sparky neighbour out to look at it and hopefully I can run the drive motor from a vfd (1.5 hp) and 240v into the transformer might run the feed motors ? Any advice/input from knowledgeable members would be appreciated.

not knowledgeable and not sure I understand... do you mean 3 feed motors on the different axis are rated differently to the main drive motor which you would like to run of a vfd... if thats the case can they be kept as is and the main motor wired up to a vfd on its own..I'm looking at upgrading my Tom Senior mill for a nice Bridgeport I've got my eye on. I was hoping to run it off a vfd, but I noticed the 3 feed motors are rated at 90volts dc, so that scuppers that idea for the moment and my wallet got a severe fright at the price of rotary phase converters.

There's a slim chance that the input transformer looks to have a 240v tapping (but 'tricity is the devil's work to me!) and I need to get my tame sparky neighbour out to look at it and hopefully I can run the drive motor from a vfd (1.5 hp) and 240v into the transformer might run the feed motors ? Any advice/input from knowledgeable members would be appreciated.

View attachment 563148

Subscribers do not see these advertisements

Yea.. I get that.. I'm sure you will come up with a satisfactory solution if you get it..andy63, that's about the size of it. The spindle motor is one and a half horsepower, 3 phase, dual voltage, so could be run off a standard vfd easily enough, but the three individual feed motors for each axis require 90vdc to run them. Most British built industrial milling machines tend to run the table feeds via a gearbox driven from the main motor (bit like a lathe) but lots of Bridgeport/turret types often have no feeds at all, or maybe just on the X axis, via a separate motor.

This mill I'm looking at is well specc'd, 3 axis feed, 3 axis dro with a separate dro for the Z axis on the quill, plus it includes a slotting head and only has one tiny mark on the table. It's a little bit overkill for what I need, but that's never stopped me in the past !

I have a Harrison M300 that I run off a vfd and my home built 2"x72" belt grinder runs from a vfd too.

If I was starting from scratch, I would be tempted to buy a rotary phase converter that would run all the 3 phase gear I would ever own and possibly a welder too, but rpc's are priced at almost £1k for a 4kw unit and a vfd is under £200.

Subscribers do not see these advertisements

Subscribers do not see these advertisements

I have small boring bars, but for very small short tapered holes I would make a custom bit from a piece of HSS square or round bar.John Barrett what would be the smallest hole you could do with a boring bar ie is 9.7 mm possible ? Can’t be a drill as it has a tapper to 11.7 over a length of 10 mm

This is my smallest 'boring bar'. It is a solid tungsten carbide miniature bar which gets used for those little 'awkward' jobs. They cost a fortune...!John Barrett what would be the smallest hole you could do with a boring bar ie is 9.7 mm possible ? Can’t be a drill as it has a tapper to 11.7 over a length of 10 mm

PH Horn or Sandvik with thro centre coolant solid carbideThis is my smallest 'boring bar'. It is a solid tungsten carbide miniature bar which gets used for those little 'awkward' jobs. They cost a fortune...!

View attachment 566661

Subscribers do not see these advertisements

Steve if you know anybody with a cnc milling machine you can generate the taper by milling with a bullnose cutter.John Barrett what would be the smallest hole you could do with a boring bar ie is 9.7 mm possible ? Can’t be a drill as it has a tapper to 11.7 over a length of 10 mm

You could use a custom made "D" bit to cut the taper ? I have a few I've made over the years, usually from silver steel, hardened and tempered. Just need a pilot hole drilling first, then follow up with the D bit, but I would recommend using a slow running drill press rather than a pistol drill if you have access to one ?John Barrett what would be the smallest hole you could do with a boring bar ie is 9.7 mm possible ? Can’t be a drill as it has a tapper to 11.7 over a length of 10 mm

Subscribers do not see these advertisements

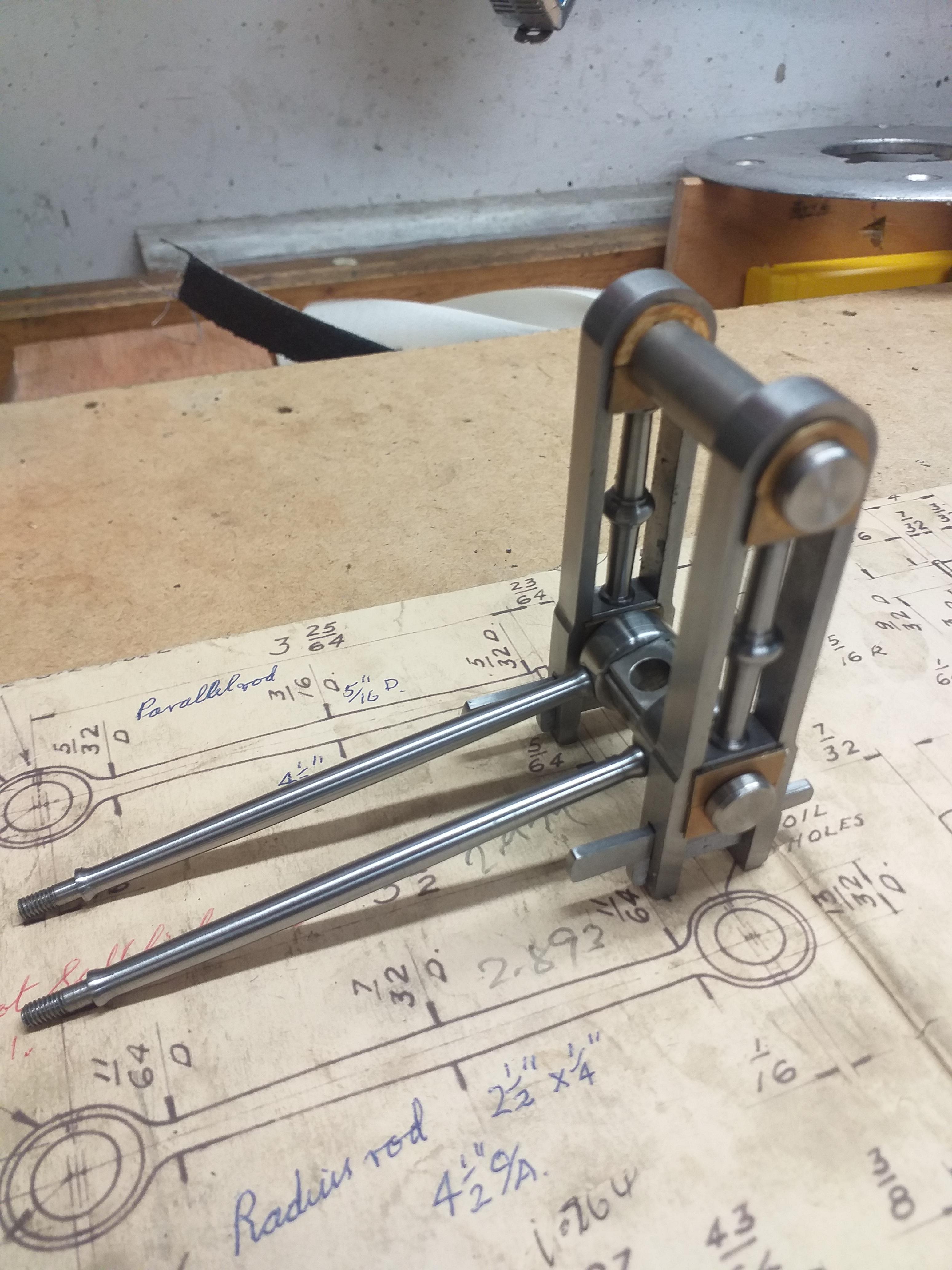

Thankyou. What's alarming is that there is a diminishing number of us left who can make something like that from scratch!Beautiful workmanship that's fantastic

Subscribers do not see these advertisements

AmazingThankyou. What's alarming is that there is a diminishing number of us left who can make something like that from scratch!

I built the latest version of the International One Metre racing yacht a few years ago, and it was so fast I couldn't control the thing! I sold it to another Club member who couldn't wait to get his hands on it!SNIP

Building a Vic smeed starlet ATM, but nowhere near your standard!

I have a myfold ml8 but would love an ml7 too.

Cheers James

Nice...I built the latest version of the International One Metre racing yacht a few years ago, and it was so fast I couldn't control the thing! I sold it to another Club member who couldn't wait to get his hands on it!

6th November 2017

Received from Mr XXXXXX the sum of £1,100 (One Thousand, One Hundred Pounds) in full payment for one ‘Alternative’ International One Metre Yacht.

As seen and approved.

Many thanks

John Barrett

View attachment 570099

Subscribers do not see these advertisements

This one 'ere. Lightning fast!Nice...

I might build a IOM yacht a the starlet is destined to reside at my dad's house...

My local club sails IOM....

What design did you use?

Mine would end up weighing 6kg!!!

Cheers James

radioyachtingnelson.com

radioyachtingnelson.com

Subscribers do not see these advertisements