- May 29, 2013

- 2,714

- 21,749

- Funster No

- 26,231

- MH

- Chausson best of Flash 10

- Exp

- Several years now

To do some waxoyl-ing I had to take off the front wheels from my 2014 Ford Transit base vehicle.

Normally when taking the nuts of any vehicles wheels I use a bit of scaffolding pole to give some leverage.

However, on the Transit, the nuts, while not slack, were not as tight as I would have imagined them to be. I'd have assumed they would need me swinging on a long scaffolding bar, but instead they loosened with a 1ft long extension on the socket wrench.

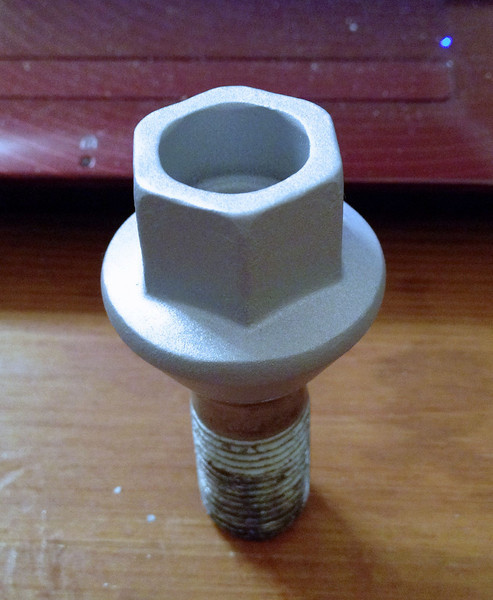

The nuts have what appears to be built-in shake-proof washers, with little ridges on them, which, when doing the nuts back up I sort of heard them "click" as they reached a tight position. Is this a new invention on wheel nuts or what ?

Normally when taking the nuts of any vehicles wheels I use a bit of scaffolding pole to give some leverage.

However, on the Transit, the nuts, while not slack, were not as tight as I would have imagined them to be. I'd have assumed they would need me swinging on a long scaffolding bar, but instead they loosened with a 1ft long extension on the socket wrench.

The nuts have what appears to be built-in shake-proof washers, with little ridges on them, which, when doing the nuts back up I sort of heard them "click" as they reached a tight position. Is this a new invention on wheel nuts or what ?