PP Bear

LIFE MEMBER

Just changed the front brake pads again. Some of you might recall my thread about my front pads delaminating at 25,000 miles. (https://www.motorhomefun.co.uk/forum/threads/ducato-owners-beware.118694/#post-1616002).

Well, I've completed just under 10,000 miles (34275 miles now on the clock) since I replaced them and wanted to give them a check to see how they held up to the mileage.

Glad I did, as they were showing signs of early delamination again. First set I checked and changed at 25000 miles and they had completely split, whereas these had done just under the 10,000 miles and started to do the same.

Maybe just a coincidence, but both times it was from the front righthand side.

Anyway, new pads done. It's such a simple job to do, well within the reach of a competent DIY mechanic.

Few photos along the way.

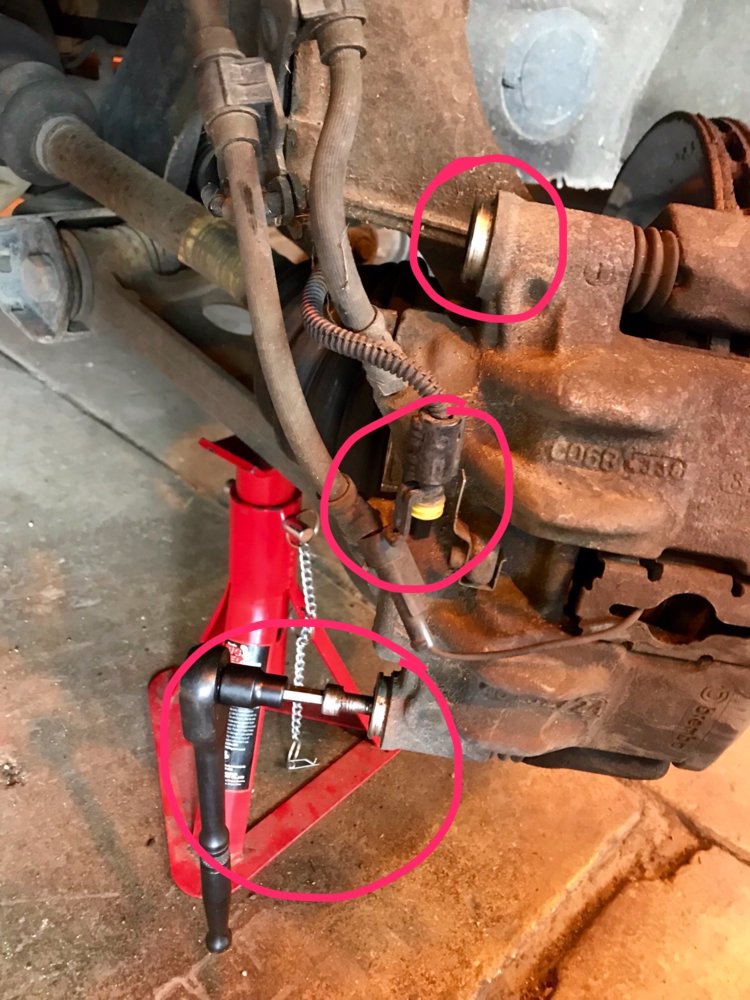

Make sure you use a suitable jack and axle stand and chock the rear wheels with the handbrake on for safety. Never ever work under an unsupported vehicle at any time.

After removing the wheel, turn the steering to make access easier.

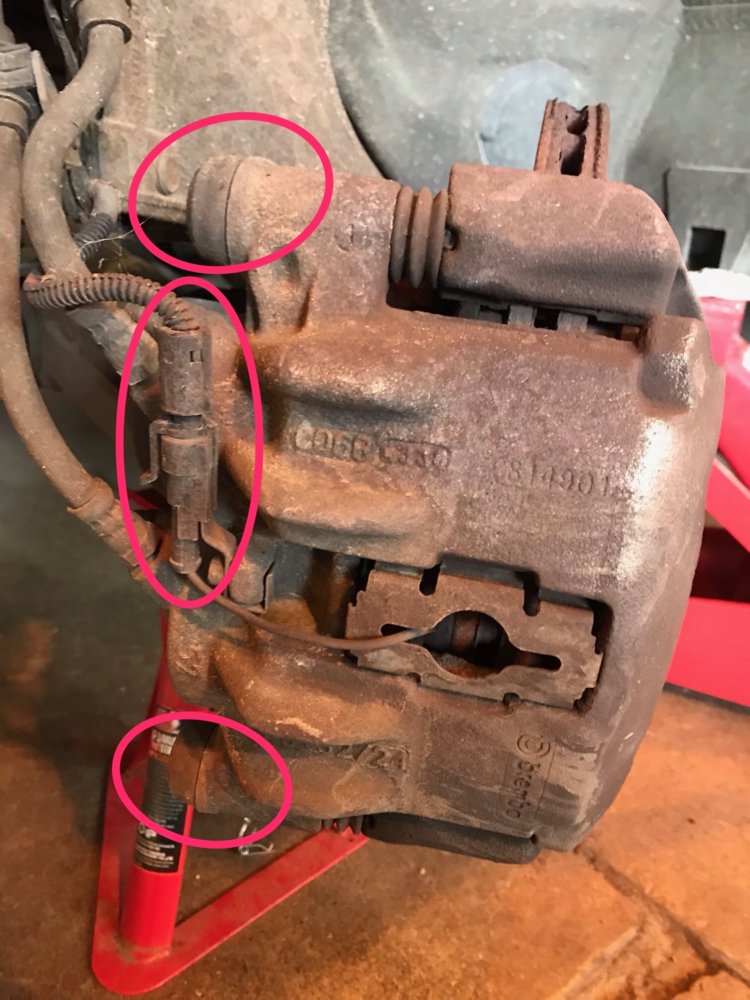

Pop off the rubber caps. Be careful not to split them. If they're split then replace them.

On the front left side, is the brake wear indicator, which needs disconnecting. There isn't a wear indicator on the other side.

Once the rubber caps are removed, you can unscrew the retaining bolts and remove them completely.

Disconnect the wear indicator wire.

Depress and remove the anti rattle spring retainer and slide it from the sensor cable.

Make sure these are serviceable. If not then they'll need replacing.

Insert a flat headed tool and gently depress the pad shroud to retract the pistons. Be sure to fully retract them to take the size of the new pads. You may require to remove the brake master cylinder cap and place a rag around it, just in case the fluid spills from the caliper pistons being compressed.

With the pistons retracted, you can easily remove the piston carrier and inspect the rubber seals. Do not let it dangle on the hoses.

It can easily sit on top of the assembly, or tied up and supported, but at no time allow it to pull, kink or dangle on the brake hoses.

You can now remove the old pads for either inspection or replacement. If you've got this far, it's worth simply replacing them.

At this point you can clean the mating surfaces with a flat tool. Do not score the disc.

The new pads in place.

Copperslip or another brake grease can be applied to the surfaces that contact the pistons and other mated surface. Be sure not to get any on either the disc or brake pad surfaces.

At this stage you can reassemble the two mated parts.

Once the assembly is together, you can put the bolts back in, noting that the new bolts have a locking compound on the threads.

Replace the rubber caps, the retaining antirattle spring and wear indicator wire.

It's an ideal time to clean the inside of the wheel and examine the inside wall of the tyre at the same time.

And apply a layer of copper grease on the inside of the wheel, where it mates with the hub. This will allow it to be freed a lot easier the next time it has to be removed.

While there is still plenty of depth and life in the pads, you can clearly see the pad has started to delaminate, only this time I've caught it before it completely fails.

The old pads waiting to be disposed of.

The pads I changed at 25000 miles, clearly showing complete failure.

Hope it might help anyone who may wish to change their own pads.

Please remember to stay safe and take extreme care when working under or around a supported vehicle

Well, I've completed just under 10,000 miles (34275 miles now on the clock) since I replaced them and wanted to give them a check to see how they held up to the mileage.

Glad I did, as they were showing signs of early delamination again. First set I checked and changed at 25000 miles and they had completely split, whereas these had done just under the 10,000 miles and started to do the same.

Maybe just a coincidence, but both times it was from the front righthand side.

Anyway, new pads done. It's such a simple job to do, well within the reach of a competent DIY mechanic.

Few photos along the way.

Make sure you use a suitable jack and axle stand and chock the rear wheels with the handbrake on for safety. Never ever work under an unsupported vehicle at any time.

After removing the wheel, turn the steering to make access easier.

Pop off the rubber caps. Be careful not to split them. If they're split then replace them.

On the front left side, is the brake wear indicator, which needs disconnecting. There isn't a wear indicator on the other side.

Once the rubber caps are removed, you can unscrew the retaining bolts and remove them completely.

Disconnect the wear indicator wire.

Depress and remove the anti rattle spring retainer and slide it from the sensor cable.

Make sure these are serviceable. If not then they'll need replacing.

Insert a flat headed tool and gently depress the pad shroud to retract the pistons. Be sure to fully retract them to take the size of the new pads. You may require to remove the brake master cylinder cap and place a rag around it, just in case the fluid spills from the caliper pistons being compressed.

With the pistons retracted, you can easily remove the piston carrier and inspect the rubber seals. Do not let it dangle on the hoses.

It can easily sit on top of the assembly, or tied up and supported, but at no time allow it to pull, kink or dangle on the brake hoses.

You can now remove the old pads for either inspection or replacement. If you've got this far, it's worth simply replacing them.

At this point you can clean the mating surfaces with a flat tool. Do not score the disc.

The new pads in place.

Copperslip or another brake grease can be applied to the surfaces that contact the pistons and other mated surface. Be sure not to get any on either the disc or brake pad surfaces.

At this stage you can reassemble the two mated parts.

Once the assembly is together, you can put the bolts back in, noting that the new bolts have a locking compound on the threads.

Replace the rubber caps, the retaining antirattle spring and wear indicator wire.

It's an ideal time to clean the inside of the wheel and examine the inside wall of the tyre at the same time.

And apply a layer of copper grease on the inside of the wheel, where it mates with the hub. This will allow it to be freed a lot easier the next time it has to be removed.

While there is still plenty of depth and life in the pads, you can clearly see the pad has started to delaminate, only this time I've caught it before it completely fails.

The old pads waiting to be disposed of.

The pads I changed at 25000 miles, clearly showing complete failure.

Hope it might help anyone who may wish to change their own pads.

Please remember to stay safe and take extreme care when working under or around a supported vehicle