Sometime in the late 60's I saw a rolling ball clock in a jewellers in Ipswich, it fascinated me watching the ball roll back and forth and I said one day I will build one.

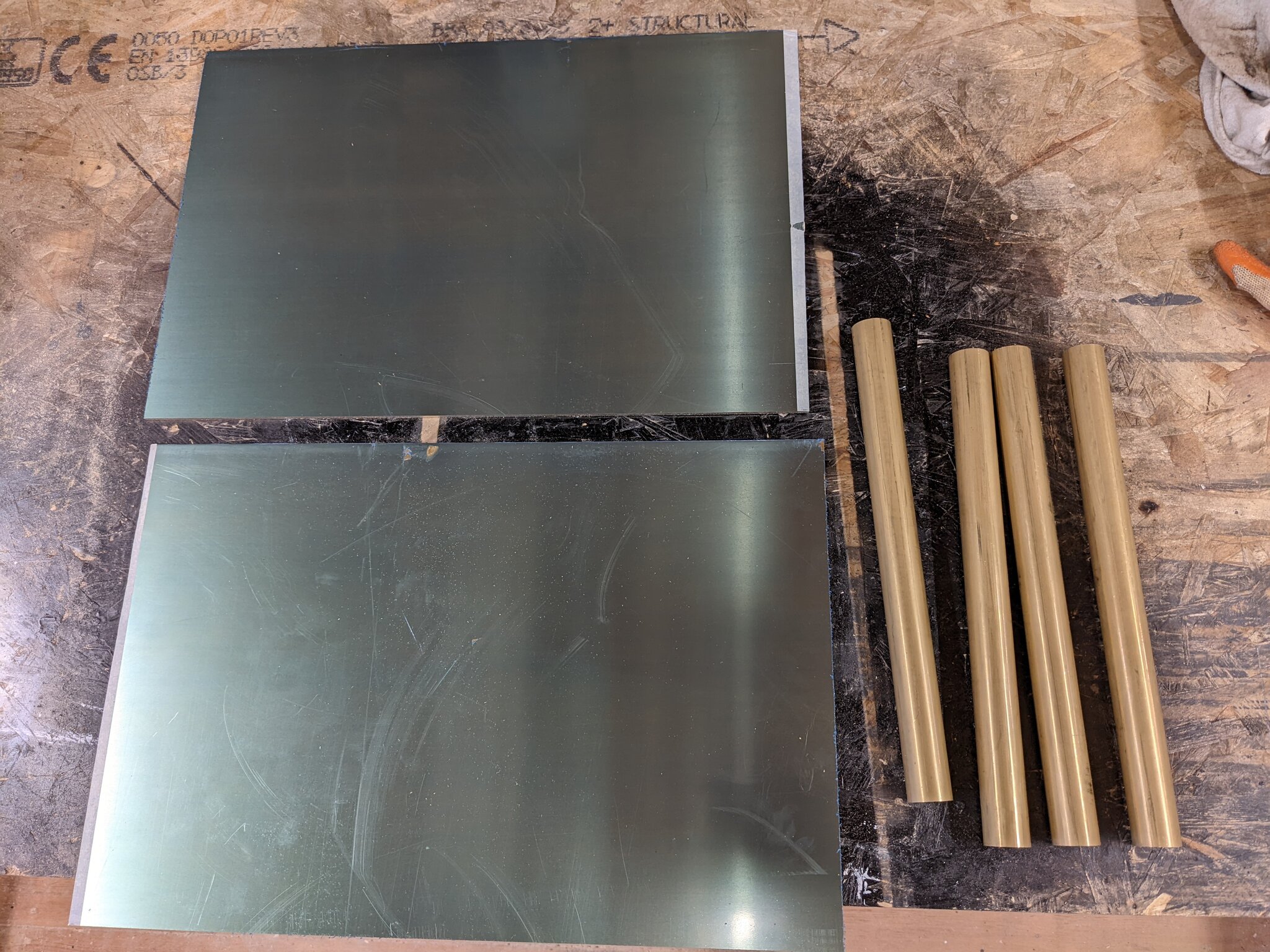

Last year I decided to finally start. I got the plans last year and last week the first bits of brass arrived, 4 lengths of 1" dia and two sheets of engraving brass all for the horrendous sum of £272.17

This is a long term project of a year or two unless

A) I lose interest

B) I run out of money

C) I pop my clogs

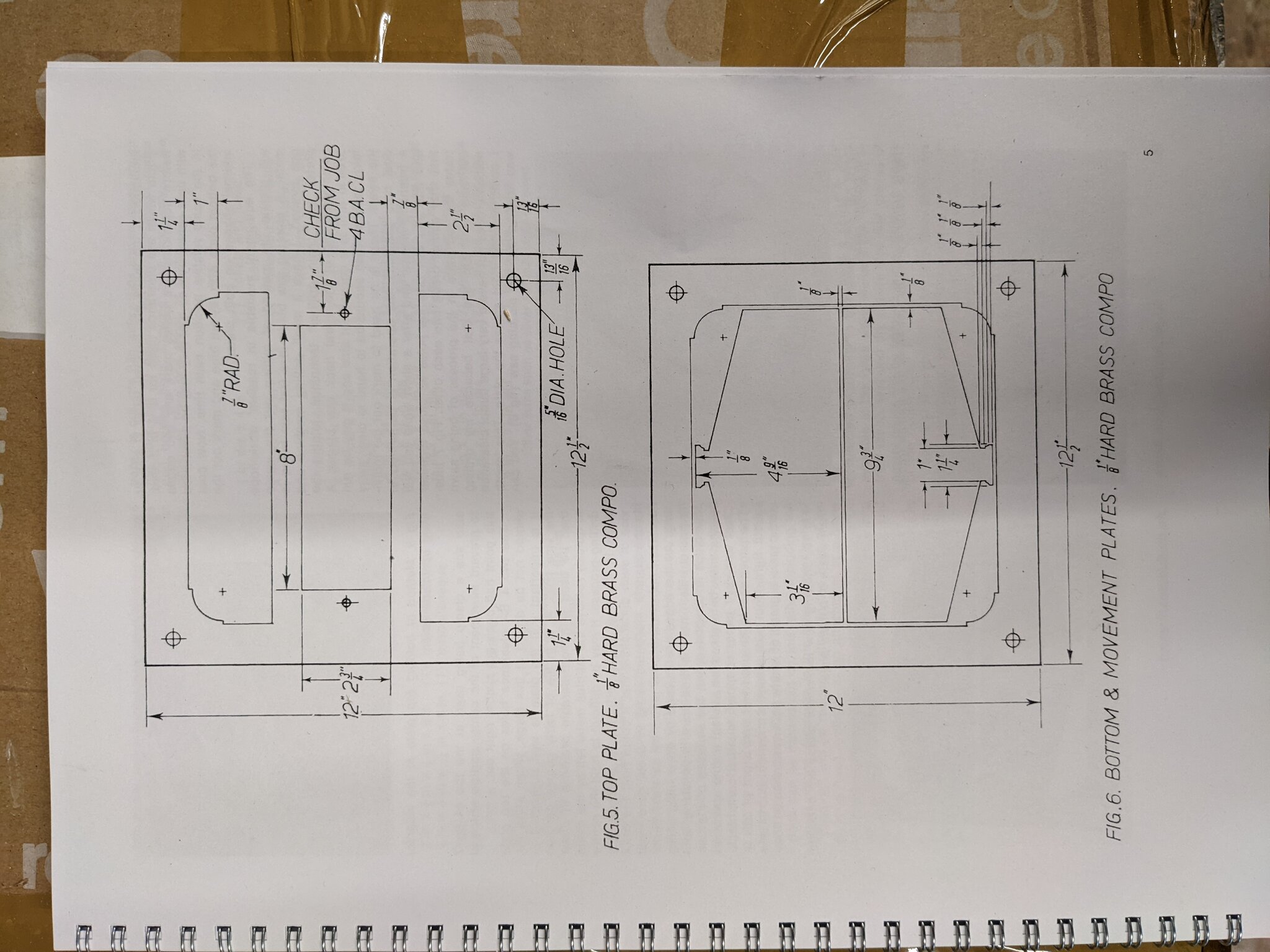

The plan for the sheet brass.

Progress so far.

And

Last year I decided to finally start. I got the plans last year and last week the first bits of brass arrived, 4 lengths of 1" dia and two sheets of engraving brass all for the horrendous sum of £272.17

This is a long term project of a year or two unless

A) I lose interest

B) I run out of money

C) I pop my clogs

The plan for the sheet brass.

Progress so far.

And

Last edited:

.

.