If like me you run lots of kit via an inverter it's worth checking that you have good contacts on all the electrical connections. Last year a fuse holder began to deform and melt causing me some angst on a hot day!

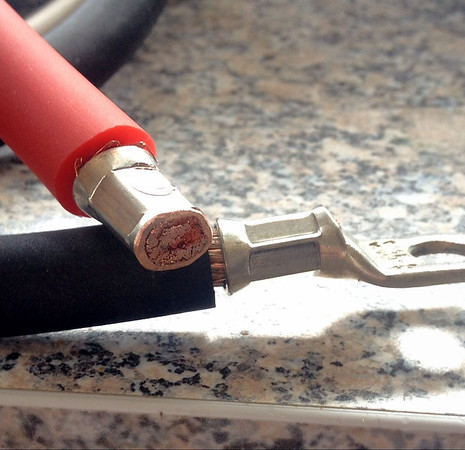

When replacing this is fuse block I tinned the end of the multiple strands on the thick cables to ensure a good contact.

Today I was checking there's no overheating!

When replacing this is fuse block I tinned the end of the multiple strands on the thick cables to ensure a good contact.

Today I was checking there's no overheating!

oh:

oh: