RogerThat

LIFE MEMBER

You may have seen my thread explaining my freezing cold bathroom (due to not having a blown air system) and the various ideas I was bounding around re fitting an electric towel rail in there to keep the chill off.

Anyway, the electric towel rail in my 'wet room' style bathroom probably wasn't a great idea and I headed off to research converting or upgrading my trusty Carver gas-only space heater in to a dual-fuel blown air system.

Turns out it appears to be a lot more simple than I first suspected.

I'll use this thread to document my retro-fit blown air system on my 1999 Swift Sundance and to highlight any pitfalls or gotchas that I encounter along the way, along with what parts are needed, costs, etc.

Here's the Carver heater in my MH, I forget the model number but it's the most basic one with just one dial to control the heat and one push button that you need to press a few times to get the fire to ignite.

You can't see too well from that photo above, but there is a wardrobe directly above the heater, and my freezing bathroom is immediately to the left of that pic.

On the rear of the heater is a removable disc, I guess Carver make/made millions of these to keep costs down.

This disc will prise off, I've not removed mine as yet (will do nearer the time).

Thanks to those of you in the other thread(s) that pointed me in the right direction for the various bits and pieces that I needed to get this job done.

As ever, I'm doing this on a budget. I'm fully aware that I won't be able to recover any money I invest in my old motorhome but I do want to make as many improvements to my motorhoming experience as I can so I see this as an investment in my future enjoyment and comfort levels more than anything else

So, with this in mind, it's my intention to use as many second hand / reclaimed parts as I can - eBay being my friend.

I'm not quite sure what the relationship with Carver and Truma is but there are a LOT of Truma parts on eBay, not so many Carver parts. Many seem to be interchangeable, especially where the ducting and outlets are concerned. However, I'm not sure about the motor assembly which connects to the rear of my heater as the Truma ones look significantly different in size and shape from that of the Carver ones.

With this in mind, my quest began for Carver-only parts.

It took a while but eventually eBay came up trumps with a Carver blown air heating kit (removed from a caravan) which also included the controls. The controls were important to me as I wanted this job to look as 'factory-fit' as I could so to have the heater controls match my existing (Clipsal-style) controls was almost essential.

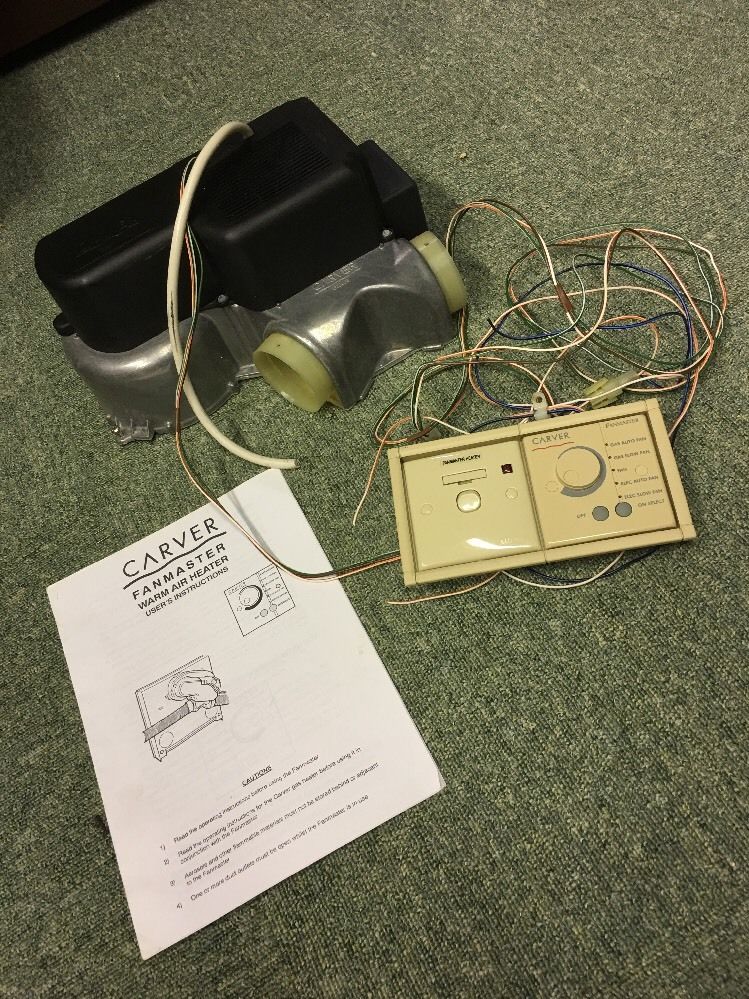

So £99 quid later and I was the proud owner of this little lot.

It's a genuine Carver Fanmaster Warm Air Heater, complete with controllers and all the associated wiring looms. It even came with an operating manual.

What it didn't come with though, was an installation manual. Thanks to @Eddystone who pointed me in the right direction for that manual, I attach that manual to this post below for completeness.

I contacted the seller in advance, and from advice gained here that £99 was a bit pricy (I still personally think that was a fair price including controls, wiring, etc) I asked the guy if he would throw in 3x outlets, some pipe/ducting clips and some ducting. Sure enough, he did!

So here's a closer more detailed look at what I ended up with.

The fan motor assembly unit itself, two outlets and a 2Kw electric heater element contained within (this is how I convert to dual-fuel heating).

I took this silver cover off and just had a quick blow out of any old dust. It was surprisingly clean inside there though.

Anyway, the electric towel rail in my 'wet room' style bathroom probably wasn't a great idea and I headed off to research converting or upgrading my trusty Carver gas-only space heater in to a dual-fuel blown air system.

Turns out it appears to be a lot more simple than I first suspected.

I'll use this thread to document my retro-fit blown air system on my 1999 Swift Sundance and to highlight any pitfalls or gotchas that I encounter along the way, along with what parts are needed, costs, etc.

Here's the Carver heater in my MH, I forget the model number but it's the most basic one with just one dial to control the heat and one push button that you need to press a few times to get the fire to ignite.

You can't see too well from that photo above, but there is a wardrobe directly above the heater, and my freezing bathroom is immediately to the left of that pic.

On the rear of the heater is a removable disc, I guess Carver make/made millions of these to keep costs down.

This disc will prise off, I've not removed mine as yet (will do nearer the time).

Thanks to those of you in the other thread(s) that pointed me in the right direction for the various bits and pieces that I needed to get this job done.

As ever, I'm doing this on a budget. I'm fully aware that I won't be able to recover any money I invest in my old motorhome but I do want to make as many improvements to my motorhoming experience as I can so I see this as an investment in my future enjoyment and comfort levels more than anything else

So, with this in mind, it's my intention to use as many second hand / reclaimed parts as I can - eBay being my friend.

I'm not quite sure what the relationship with Carver and Truma is but there are a LOT of Truma parts on eBay, not so many Carver parts. Many seem to be interchangeable, especially where the ducting and outlets are concerned. However, I'm not sure about the motor assembly which connects to the rear of my heater as the Truma ones look significantly different in size and shape from that of the Carver ones.

With this in mind, my quest began for Carver-only parts.

It took a while but eventually eBay came up trumps with a Carver blown air heating kit (removed from a caravan) which also included the controls. The controls were important to me as I wanted this job to look as 'factory-fit' as I could so to have the heater controls match my existing (Clipsal-style) controls was almost essential.

So £99 quid later and I was the proud owner of this little lot.

It's a genuine Carver Fanmaster Warm Air Heater, complete with controllers and all the associated wiring looms. It even came with an operating manual.

What it didn't come with though, was an installation manual. Thanks to @Eddystone who pointed me in the right direction for that manual, I attach that manual to this post below for completeness.

I contacted the seller in advance, and from advice gained here that £99 was a bit pricy (I still personally think that was a fair price including controls, wiring, etc) I asked the guy if he would throw in 3x outlets, some pipe/ducting clips and some ducting. Sure enough, he did!

So here's a closer more detailed look at what I ended up with.

The fan motor assembly unit itself, two outlets and a 2Kw electric heater element contained within (this is how I convert to dual-fuel heating).

I took this silver cover off and just had a quick blow out of any old dust. It was surprisingly clean inside there though.