Riverbankannie

LIFE MEMBER

This isn’t Motorhome related but both a warning and a question why?

We have 6 downlights in our bathroom running in 2 sets of 3 off a transformer for each set.

One by one these have been failing, and it’s not been a failure of the lightbulb (halogen type).

We have read that the transformers are not reliable so have decided to replace with 240v led ones.

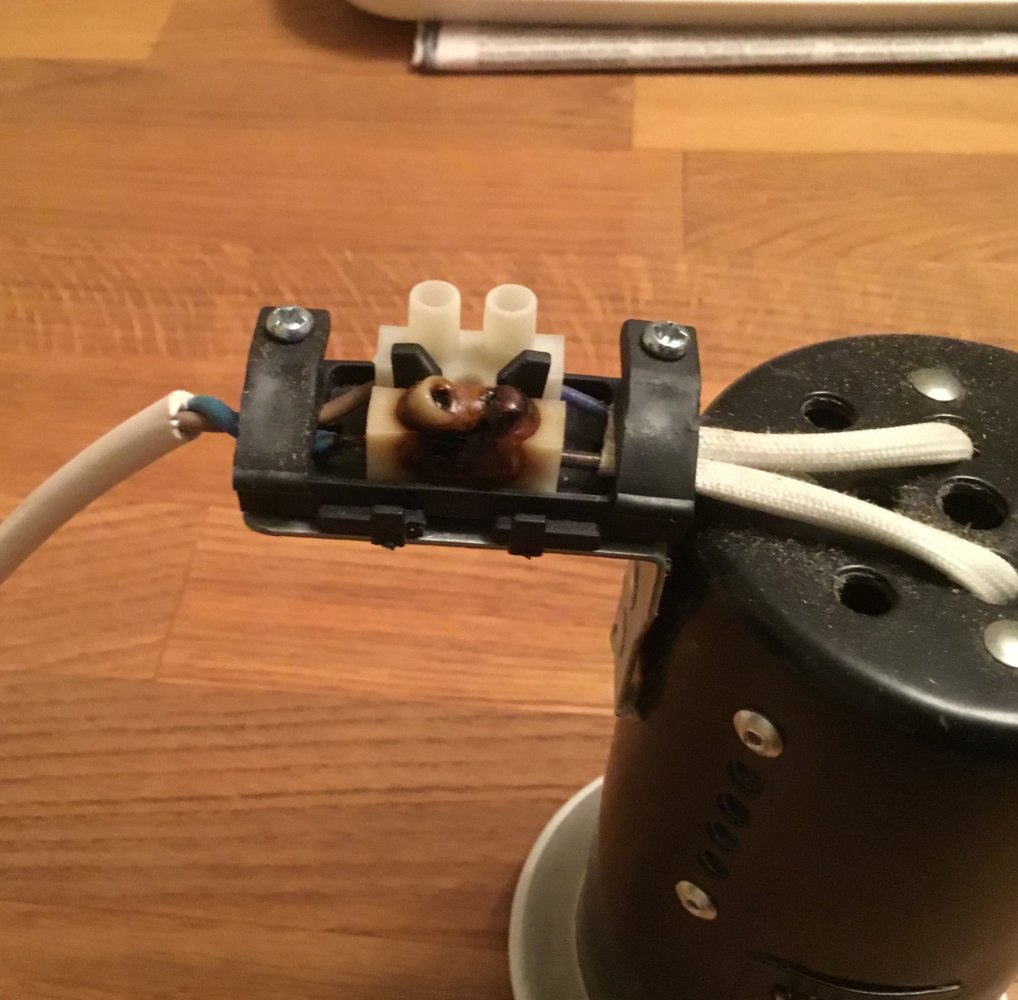

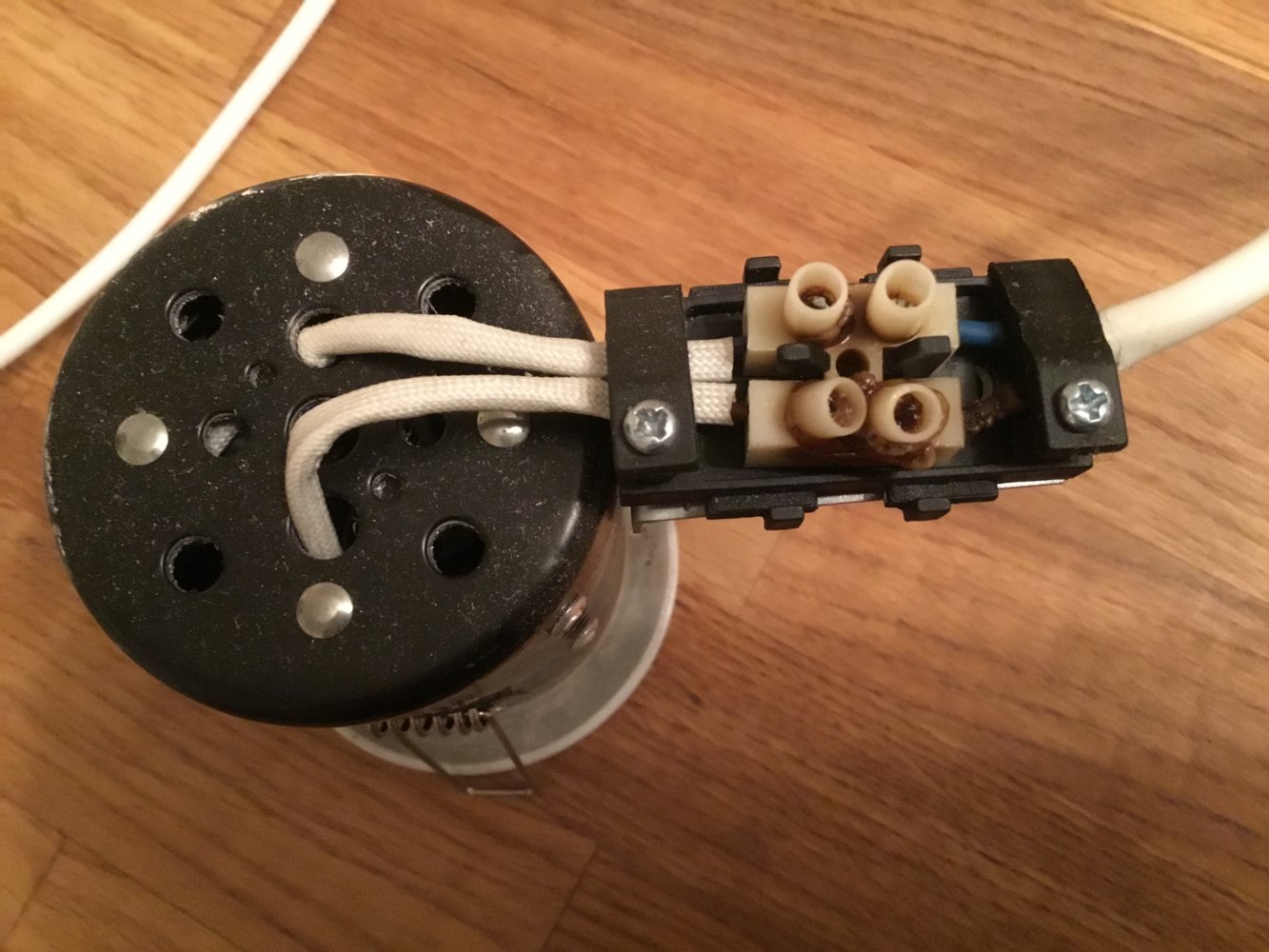

On removal of all the canisters, we found that all we found that all of the junction boxes, which connect the wire to the lamp holder, have signs of heat damage. It’s a bit scarey to think that this has been going on in our loft. There was no insulation covering them. The transformers have failed on all but one output.

So the question is, did the failure of the transformer cause the heating at the junction block or was it the other way round?

Either way, it’s not nice to think that this has been happening! In one or two instances, both terminals in the block have melted like this.

These lights are wired together with the bathroom fan, to one trip on the main board but this has never been tripped out.

We have 6 downlights in our bathroom running in 2 sets of 3 off a transformer for each set.

One by one these have been failing, and it’s not been a failure of the lightbulb (halogen type).

We have read that the transformers are not reliable so have decided to replace with 240v led ones.

On removal of all the canisters, we found that all we found that all of the junction boxes, which connect the wire to the lamp holder, have signs of heat damage. It’s a bit scarey to think that this has been going on in our loft. There was no insulation covering them. The transformers have failed on all but one output.

So the question is, did the failure of the transformer cause the heating at the junction block or was it the other way round?

Either way, it’s not nice to think that this has been happening! In one or two instances, both terminals in the block have melted like this.

These lights are wired together with the bathroom fan, to one trip on the main board but this has never been tripped out.